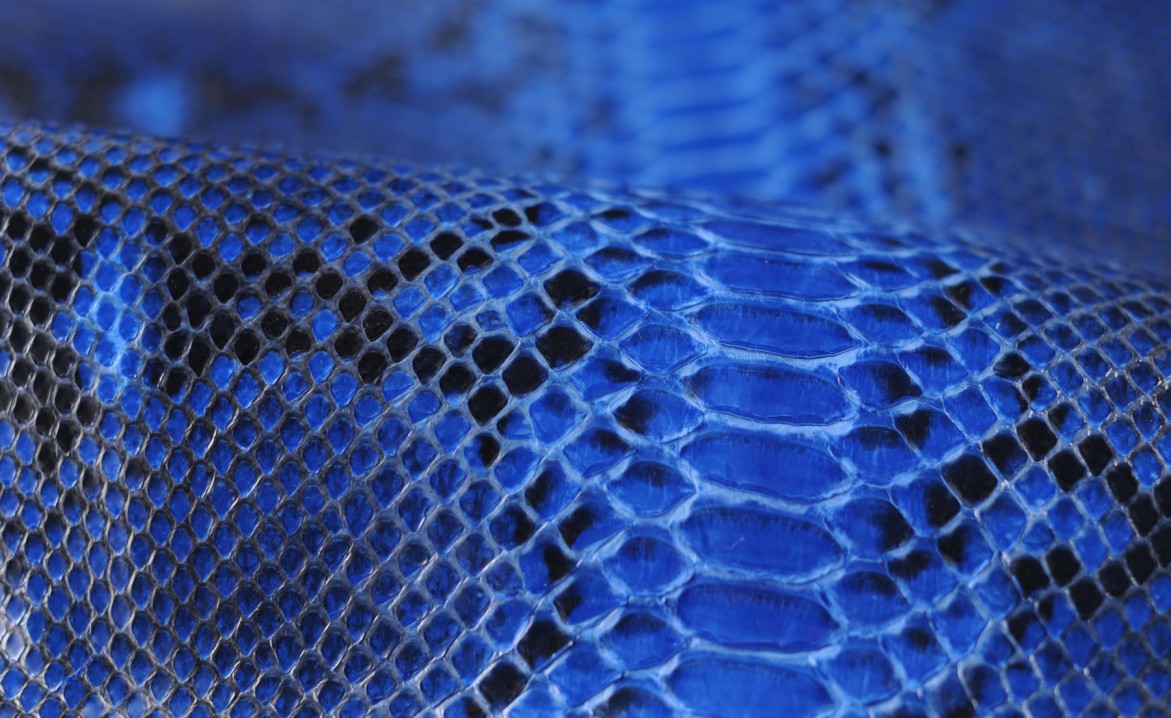

The quality of Caravel's leathers is the result of meticulous control phases throughout the supply chain

To achieve the level of quality required by luxury brands, Caravel provides a rigorous leather control process. Its internal analysis laboratory and tailor-made tests on leathers confirm the company’s ability to adequately meet the needs of the luxury market.

Multiple control phases

Controls take place during the various leather processing phases, from the selection of raw materials to the finished product.

-

- Raw materials

The selection of raw materials is made directly at the supplier, in the country of origin of the skins. In the tannery, the staff checks that the quality level of the raw leather is in compliance with the purchase. - Semi-finished:

The staff selects the crust leather by size and quality, based on customer requirements and usage specifications. - Finished product

After finishing, the leathers are tested in the laboratory to verify their physical and chemical resistances according to the technical specifications required. The Quality Control team checks the conformity of the finished product based on the specific requirements of the customer.

- Raw materials

New technologies

Aiming for innovation means equipping yourself with tools that keep up with technological evolution. Over the years, Caravel has invested in state-of-the-art equipment to match its leathers. Ensuring the quality control phase of leathers can count on an efficient and well- equipped in-house analysis laboratory.

Customized tests

The relationship with the customer is at the heart of Caravel’s commercial proposal, and for this reason, the personalization of leathers is not just a matter of style, but also quality control. The company provides an analysis service compliant with the different technical specifications provided for each brand and each type of use of the leather.